MANUFACTURING

FOR THE FUTURE

Precision moulds and injection molding solutions powering everything from automotive components to consumer appliances. Trusted by industry leaders worldwide.

Our Trusted Partners

About

Vinayak

Vinayak Technoplast is a premier one-stop ecosystem for the global plastic manufacturing industry. Inspired by the engineering vision of Mr. Arjun Kumar Agarwal (IIT-BHU) and driven by Mr. Sandeep Agarwal, we transcend traditional moulding to deliver high-precision, turnkey solutions from concept design to final assemblies all under one roof.

Why Industry Leaders Choose Us

Proven capabilities backed by real metrics

Parts Delivered

We have successfully manufactured and delivered over 100 million precision-molded parts to automotive, medical, and industrial clients, maintaining consistent quality throughout.

Quality Pass Rate

Our rigorous quality control processes ensure that 99.9% of our parts pass inspection on the first attempt, minimizing rejections and ensuring reliability for our clients.

Max Clamping Force

Our heavy-duty 850-ton and many other injection molding machines enable us to produce large, complex parts that many competitors cannot handle, giving you access to advanced manufacturing capabilities.

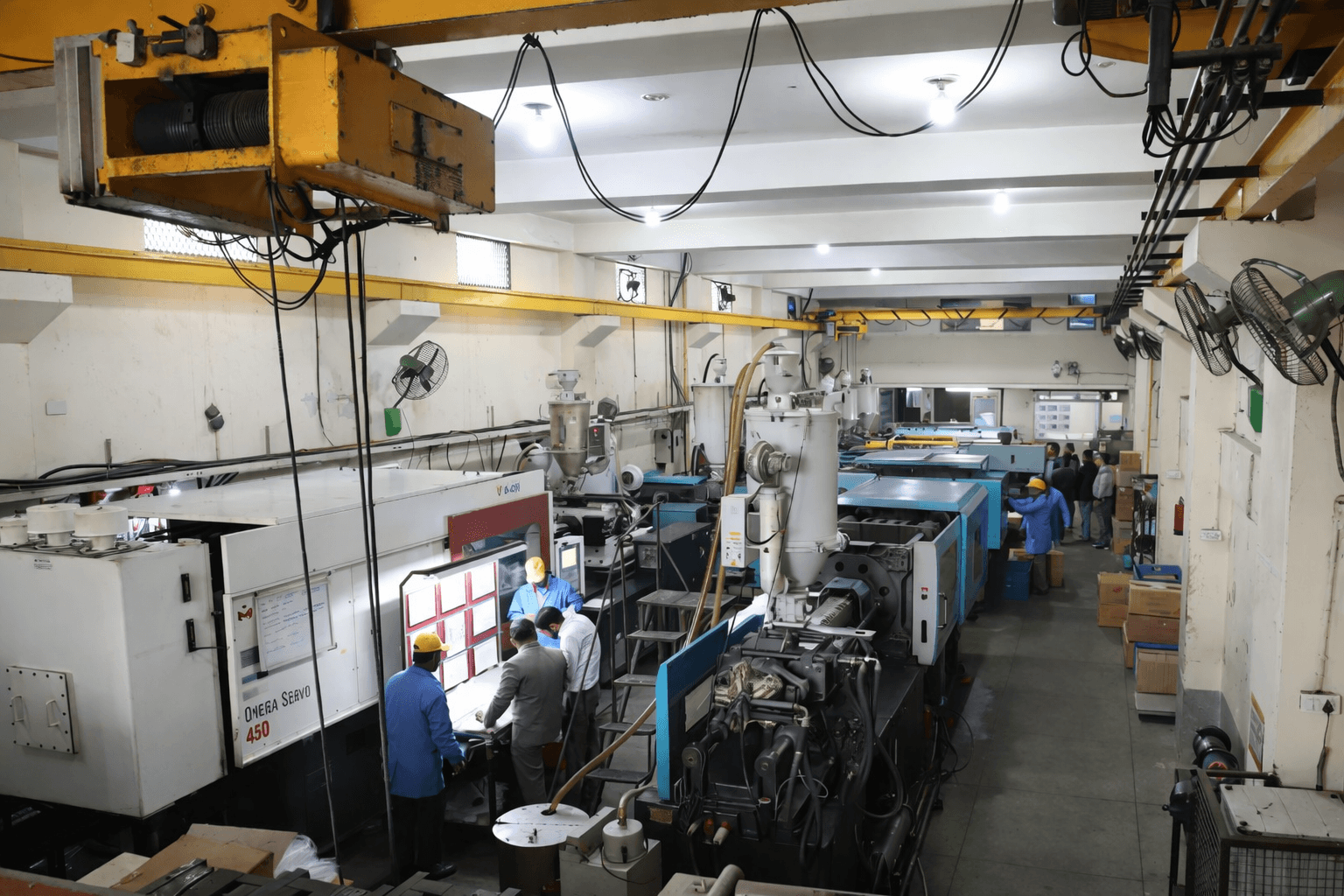

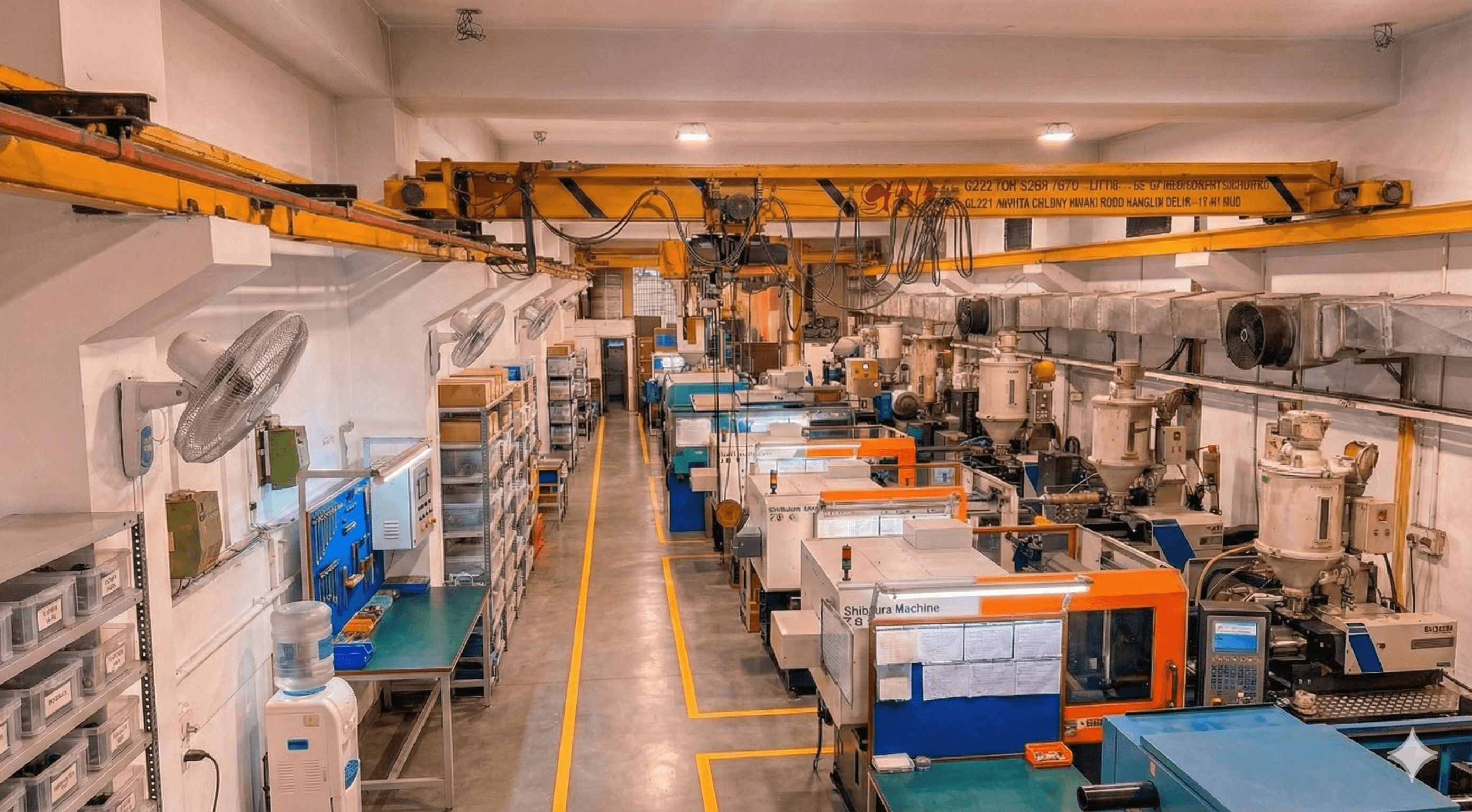

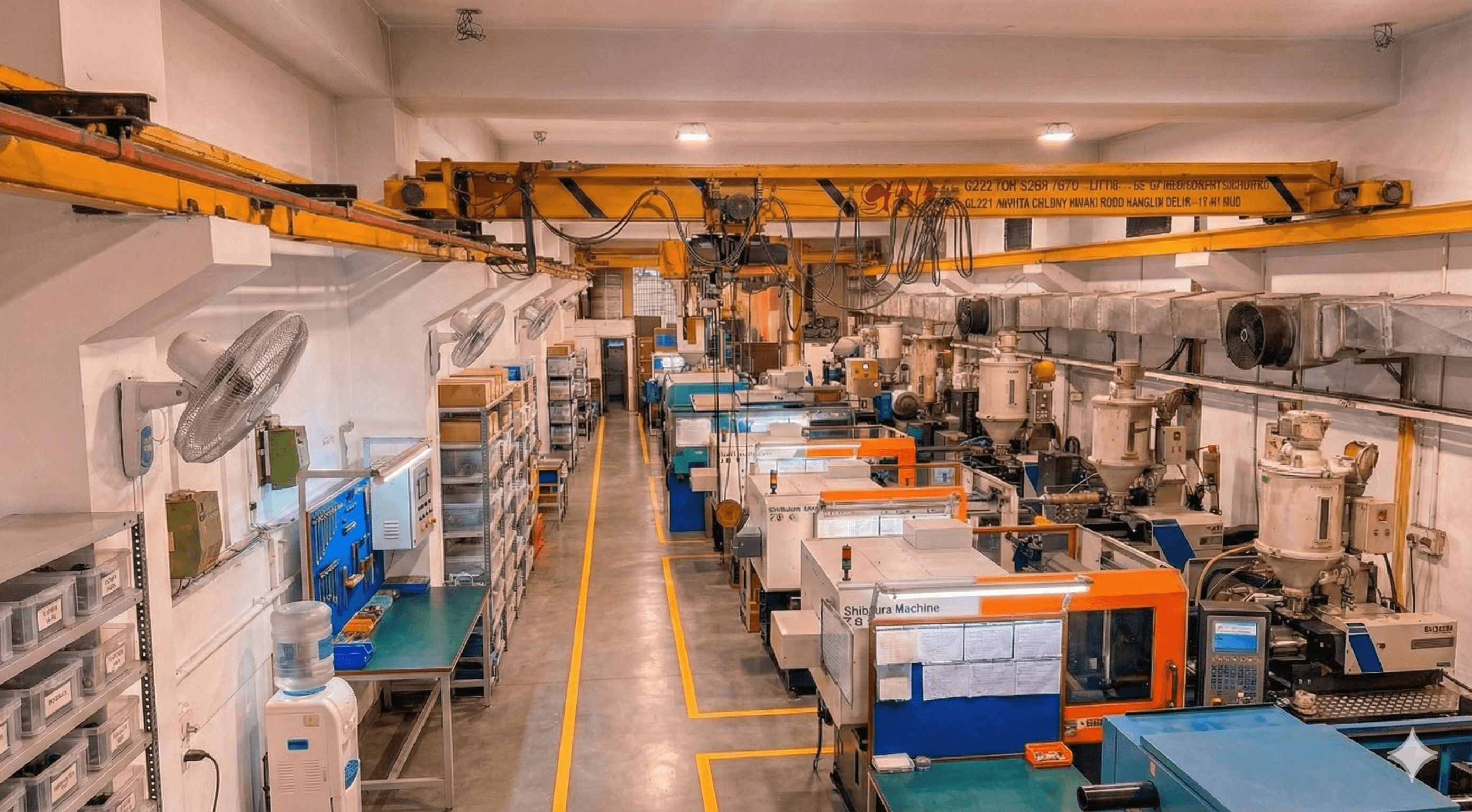

Manufacturing Facility

Our strategically located 35,000 sq. ft. facility in Delhi NCR is equipped with state-of-the-art infrastructure for design, mold development, and high-volume production.

High-Performance Machines

Our facility houses 30+ injection molding machines ranging from 60 to 850 tonnes, allowing us to handle projects of any size and complexity with optimal efficiency.

Zero-Defect OEMs

We maintain zero-defect delivery records with 5+ major OEMs in automotive and medical sectors, demonstrating our commitment to excellence and reliability.

Engineering Precision

Over 30 years of specialized experience in precision injection molding. Our engineering team has mastered the art of producing complex components with tight tolerances for demanding industries.

Toolroom Lead Time

Our in-house toolroom delivers rapid mold development in just 4-6 weeks, significantly faster than industry standards, helping you get to market quickly.

Our Equipment

Our facility houses 30 injection molding machines ranging from 60 to 850 tons, allowing us to handle a wide variety of project sizes and complexities.

Tonnage Range

Tonnage Range

Tonnage Range

Tonnage Range

Our Main Advantages

Expert R&D Team

Our dedicated R&D team, comprised of over 40 professionals, provides personalized, one-on-one service to meet your specific needs.

Cost-Effective Solutions

Achieve substantial savings of 30-50% with our optimized production processes, making your projects more economical.

Quick Turnaround

For time-sensitive projects, we excel in delivering rapid production turnaround times, ensuring your deadlines are met.

OUR CORE PRODUCTS

We produce a wide range of high-quality products designed to meet the needs of industry and business (B2B) customers. Each of our products is developed through a precision manufacturing process and rigorous quality testing.

MEDICAL INDUSTRY COMPONENTS

Critical items such as suction units, PC jars, needle cutters (Nil-Sharps), etc. ensuring strict adherence to quality standards for our medical partners

MASS CONSUMER PRODUCTS

Such as switches, energy meters, LED light housings, and multi-plugs.

AUTOMOTIVE EXTERIOR PARTS

High-precision parts such as visors, headlamps, tail lamps, reflectors, etc, serving two-wheelers, four-wheelers, and tractors

PRECISION INDUSTRIAL COMPONENTS

Mechanical and technical parts for industrial machinery, vehicles, or heavy equipment.

Latest Insights

Stay updated with our latest news and insights